INSULATED SANDWICH ROOF AND WALL PANELS

Shuban Infra Engineering Corporation manufactures, supplies, and offers turnkey contracting for a variety of Insulated Sandwich Roof and Wall Panels, ranging in thickness from 25 mm to 200 mm. These panels are made using Polyurethane (PUF), Polyisocyanurate Foam (PIR), and Rock Wool, and are available with facing materials such as Galvalume, Galvanized, S.S 304, and Aluminum.”

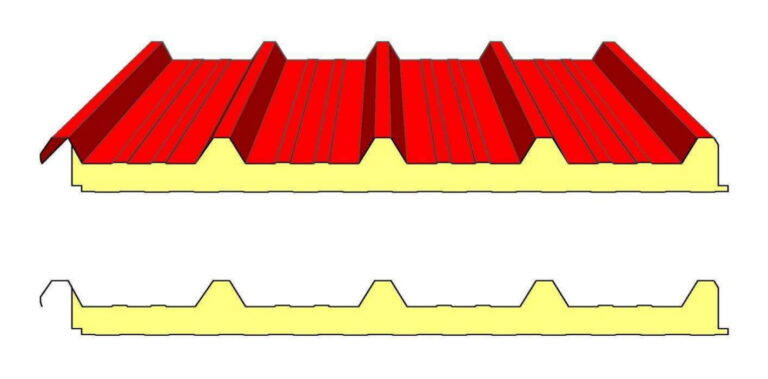

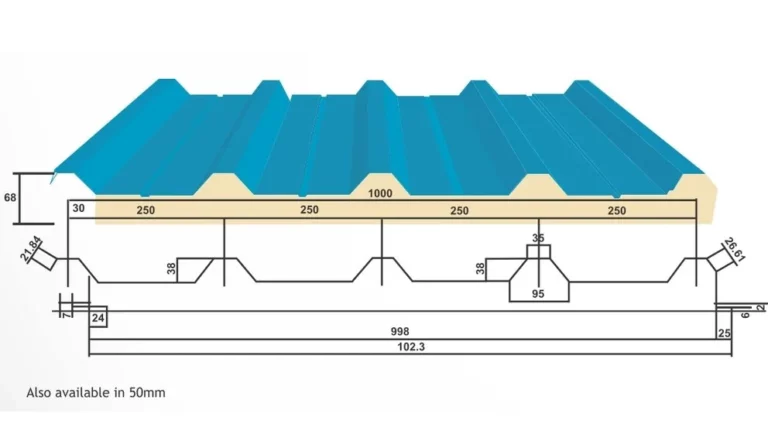

ROOF PUF / PIR PANELS

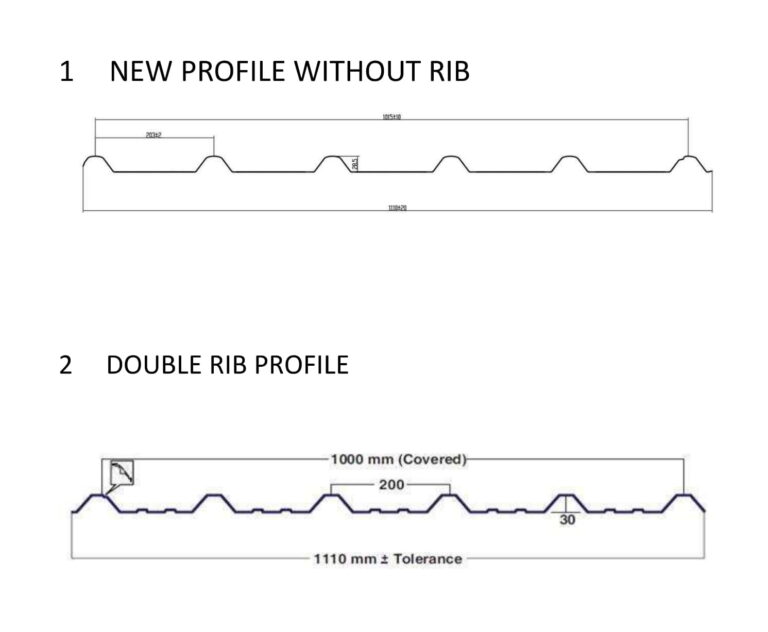

Metal-faced sandwich panels are the system of choice for large industrial buildings, refrigerated warehouses, cold storages, cold rooms, clean room office blocks, exhibition halls, fair pavilions, schools, sports complexes, and commercial buildings. These panels are also suitable for facades and partitions. The aluminum, steel, or stainless steel facings themselves are surface coated and can be manufactured with profiles of various depths, leading to a higher load-bearing capacity.

Insulated sandwich panels are complete with specially formed tongue-and-groove joints, ensuring a perfect fit and maximum integrity. The detailed specifications of the panels are as follows:

| Sl.No | Description of Material | Puff Panels | PIR Panels | Rockwool Panels |

|---|---|---|---|---|

| 1 | Density of the Panels | 40 Kgs M3 +-2 | 42 Kgs M3 +-2 | 80 to 100 KgsM3 |

| 2 | Thickness of the Panels | 25,30,40,50,60 80 ,100, 120 mm | 25,30,40,50,60 80 ,100, 120 mm | 50, 60, 80 ,100, 120 mm |

| 3 | Facing Material | PPGL, PPGI, S.S 304, Aluminum | PPGL, PPGI, S.S 304, Aluminum | PPGL, PPGI |

| 4 | Steel Thickness | 0.30.040,0.50, & 0.60 mm | 0.30.040,0.50, & 0.60 mm | 040,0.50, & 0.60 mm |

| 5 | Length of the Panels | Standard up to 6Mtr Max. 12 Mtr | Standard up to 6Mtr Max. 12 Mtr | Standard up to 6MtrMax.10Mtr |

| 6 | Width of the Panels | 1000 mm | 1000 mm | 1000 mm |

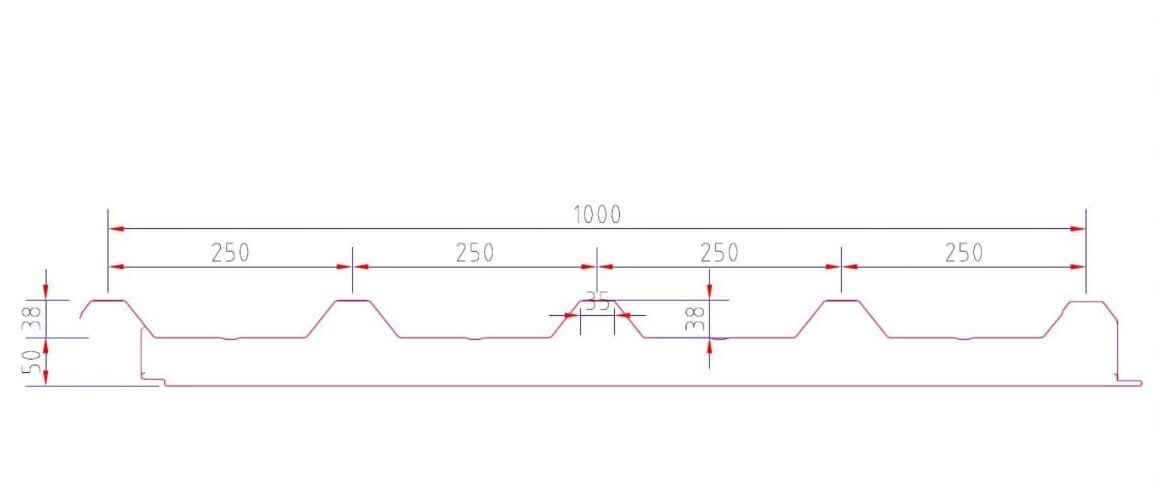

WALL/PARTITION / CIELING – PANELS

Metal-faced Sandwich panels are the system of choice today for large Industrial Buildings, Refrigerated Warehouses, Office blocks, Exhibition halls, Fair Pavilions, Schools, and Sports Complex, Commercial Building. The Aluminium or Steel & S.S facings themselves are surface coated and can be manufactured with profiles of various depths leading to a higher load-bearing capacity Insulated Sandwich Panels come complete with specially formed tongue-and-groove joints ensuring a perfect fit and maximum integrity, The raw material used for manufacturing Puf/PIR Panel is CFC free and fire retarded grade. Panels are provided with Tongue & Grove joints and specially designed Camlocks to enhance airtight assembly. Sandwich Panels are available with pre coated GI sheets, SS sheets. The detailed specifications of panels are as below :

| Sl.No | Description of Material | Puff Panels | PIR Panels | Rockwool Panels |

|---|---|---|---|---|

| 1 | Density of the Panels | 40 Kgs M3 +-2 | 42 Kgs M3 +-2 | 80 to 100 KgsM3 |

| 2 | Thickness of the Panels | 40, 50, 60, 80,100, 120 .150,200 mm | 40,50,60,80 ,100, 120.150 mm | 50, 60, 80 ,100, 120 mm |

| 3 | Facing Material | PPGL, PPGI, S.S 304, Aluminum | PPGL, PPGI, S.S 304, Aluminum | PPGL, PPGI |

| 4 | Steel Thickness | 0.30.040,0.50, & 0.60 mm | 0.30.040,0.50, & 0.60 mm | 040,0.50, & 0.60 mm |

| 5 | Length of the Panels | Standard up to 6Mtr Max. 12 Mtr | Standard up to 6Mtr Max. 12 Mtr | Standard up to 6MtrMax.10Mtr |

| 6 | Width of the Panels | 1000 /1130mm | 1000 /1130mm | 1000/1130 mm |

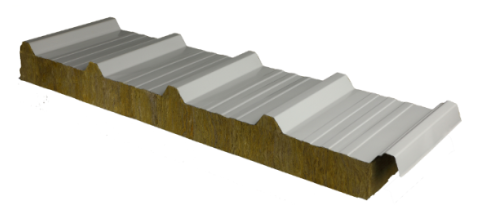

Fire Proof Rockwool Panel

The Fireproof Rockwool / Wall Sandwich Panel is one of the most economical solutions to achieve maximum protection against fire with a very simple installation. It can resist in contact with the fire for 120 minutes without losing its structural properties. This protection is achieved with a quick and easy installation that takes advantage of the tongue and groove of the Sandwich Panels to achieve total insulation. The top and bottom of the Rockwool Sandwich Panels are galvanized pre-painted steel. The core material is Rockwool with Density of 96±2kg/m3, the Rockwool is upright against the surfaces. The detailed specifications are as below :

| Specifications | |

|---|---|

| Thermal performance and strength | At 250C mean temperature thermal conductivity varies between 0.031W/mk and 0.036W.mk depending upon the density of the material. |

| Acoustic PerformancePanel length available | Alfa panels offer excellent sound absorption. The Noise reduction Coefficient (NRC) range from 0.80 to 0.95. |

| Fire Performance | Alfa panels do not contribute in any way to the spreading of fire. It does not shrink, stretch or deform when exposed to fire. It does not cause smoke or any burning droplets in case of fire. It significantly contributes to improved fire safety. |

| Resistance to moisture | Water absorption by partial immersion: 0.5kg/m2. Water absorption by full immersion: 10% to 11.5% of weight (tests done as per BS2972) |

| Storage | To store for long duration, Alfa panels should be stored indoor. If stored outside, the panels should be stacked clear of ground and covered with a securely anchored weather proof sheet. The panels should not be left exposed to weather. |

| Non Toxic | Alfa panels are not hazardous to health and do not contain asbestos. |

| Environmental impact | Alfa panels are free from CFCs, HFCs and HCFs and contain phenol resins within the permissible limits. |

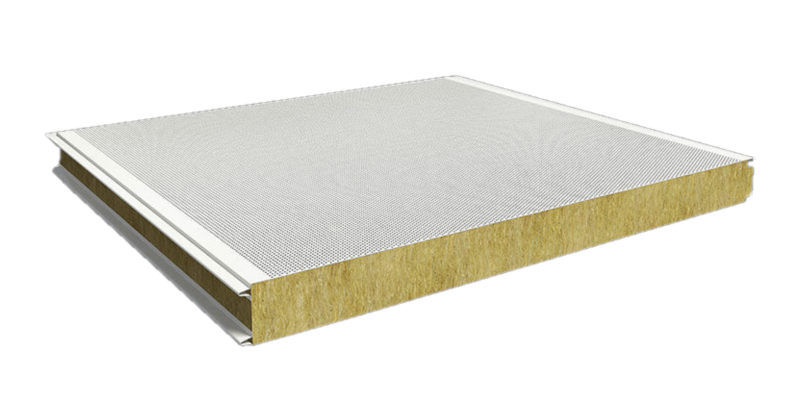

Sound Proof Rockwool Panel

Shuban Acoustic panel with rockwool Infills combine optimal density, random fibre orientation, and excellent fit to provide a significant improvement in sound absorption when used within the troughs of perforated metal roof decks. The product is wrapped in a factory-applied acoustically transparent white tissue facing for improved aesthetics and for the best performance. The detailed specifications of panels are as below :

| CHARECTERISTICS | SPECIFICATION |

|---|---|

| Panel Sizes | 3960 x 500, 2960 x 500, 2460 x 500, 1960 x 500 mm |

| Panel Thickness | 80mm | 100 mm | 120 mm |

| Wind Load | Designed as per IS 875 Part-III, 1987 |

| Sound Proofing | Class -A4 |

| Sound Deadening | Class -B2 |

| Type of Wall | Double skin insulated wall |

| Facing Sheet | Plain metal sheet / GI sheet/Aluminium , 0.5 to 1.2 mm thick |

| Backside Sheet | Perforated sheet/ GI sheet/Aluminium with 22-46 % open area |

| Infill / Core | Rock wool Confirming to IS-8183 & BS 476 of varies density and Thickness. Rock Wool covered with Fiber tissue paper fire-resistive. |

| Cover | Water repellent tissue paper for infill material lamination,50-micron thickness |

| Sound Damping | High density mass loaded vinyl barrier of 2 MM thickness |

| Joint | Each panel having a tongue & groove to join perfectly with each other |

| Gasket | The panel and structure having neoprene rubber gaskets at the joint to block noise leakage. |

| Vertical Post/ Structure | The structure is of ‘H’ profile in which acoustic panel slides longitudinally. |

| Finish | All metallic surface/parts are galvanized / powder coated / painted in desire shade. |

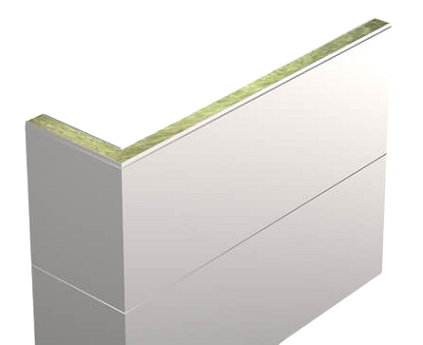

CORNER PANEL

The corner panel is nothing but corner connections with the corner panels are lockable. It aims to ensure not even a single panel is wasted in assembly and provide ease of assembly. A specially designed corner panel ensures air tight between panels and provides a uniform straight line. This allows high insulation and thus minimizes the energy consumption of Cold Air Warehouses. Infrastructure for every wiring installation inside the panel can be created (hidden installation application). The detailed specifications of panels are as below :

| Specifications | |

|---|---|

| Panel thickness available | 30mm, 40mm, 50mm, 60mm, 80mm, 100mm, 120mm |

| Panel width available | 1060mm |

| Panel length available | 2000mm-12000mm |

| Average density | 40± 2kg/m |

| Thermal conductivity | 0.024-0.03 W/m |

| Temperature range | -40+800C |

| Free from CFC | CFC free |

| Type of foam | B1, B2, B3, PIR |

| Heat transfer co-efficient | -0.022W/M2*k |

| Pressure | 0.10Mpa |

| Cubic Area Change | 1%(-30 C – 100 C/96h) |

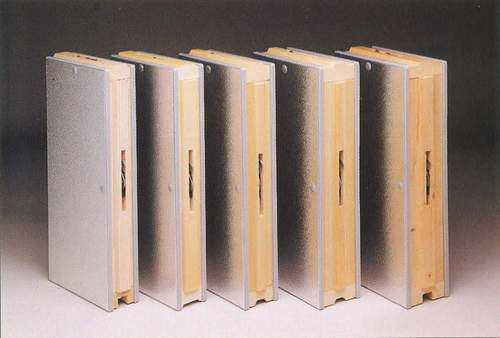

Camlock Panel

Specially designed eccentric lock mechanism ensures airtight between joints. Tongue and groove with specially designed cam lock provided. The cam lock fasteners come in pairs, a male cam lock latch, and a female cam lock pin. Insulated panels are joined together required lengths to assemble peripheral walls, partition walls, ceilings and floor. It is well designed Tongue & Groove system which utilizes the Cam locks to achieve superior tightness and uniform line. Panels slip into place allowing for easy and rapid installation, whilst improving structural strength and thermal efficiency. The detailed specifications of panels are as below :

| Specifications | |

|---|---|

| Panel thickness available | 30mm, 40mm, 50mm, 60mm, 80mm, 100mm, 120mm |

| Panel width available | 1060mm |

| Panel length available | 2000mm-12000mm |

| Average density | 40± 2kg/m |

| Thermal conductivity | 0.024-0.03 W/m |

| Temperature range | -40+800C |

| Free from CFC | CFC free |

| Type of foam | B1, B2, B3, PIR |

| Heat transfer co-efficient | -0.022W/M2*k |

| Pressure | 0.10Mpa |

| Cubic Area Change | 1%(-30 C – 100 C/96h |

POULTRY HOUSE INSUATED SANDWICH PANELS

Shuban Sandwich Panels are typically single piece prefabricated, modular, factory-made units which consists of an insulating layer o rigid Puf foam of high-density Rockwool between two layer of metal sheet. Insulation core provides effective thermal insulation& long-lasting string bonding for better structural stability to facilitate higher loading and wider spans. It is highly suitable for energy saving. Faster construction & cost effectiveness. Building when Collaborated with Cooling Pad Cn reduce temperature up to 15 Degree. We can supply Prefabricated with Environment Controlled Atmosphere, Flexi Controlled Atmosphere, Open Atmosphere Poultry Shed.

PUF SLABS

PUF slabs are the most economical thermal insulation material. Rigid Polyurethane Foam slabs are used for floor and under deck insulation. PUF slabs also available with craft paper or aluminum foil lamination

PUF Insulation slabs are made up of Rigid Polyurethane Foam (RPUF) insulation is the best solution for Primary Insulation need.

These RPUF Slabs are design for a quick and easy installation are bonded with high pressure injected polyurethane foam with plastic / paper cover to give uniform slab.

Advantages

- Fast installation High impact resistance with outstanding load bearing capacity.

- Odorless and Hygienic.

- Long life / superior durability.

- Applications:Insulation packing, floor insulation etc.

- Thermal Control:-40ºF (-40ºC) to 104ºF (+ 40ºC).

- Energy Savings: As much as a 20 % reduction in an energy use.

- Thickness: 25mm to 150mm.

- Standard Sizes:8ft x 4ft (L x W) (Customization available)

- Density:40 ± Kgs /cu M (customized as per application requirement)

- Quality Standards:Design as per CFIA and USDA standard.