SHUBAN INFRA – PRE ENGINEERING BUILDING

Shuban Infra -Pre-Engineered Buildings is specialized in design, manufacturing and installation services of Pre-Engineered Buildings and Structural Steel projects. The foundation of the company has been laid by professionals having rich experiences in business development, project management, project execution and customer relationship. The necessity to meet the growing demand of Pre-Engineered Buildings in India and to provide complete end to end solution to clients for their buildings requirements has been the main reason for emergence. Our aim is not merely supply the buildings to customers but to put in use our expertise at each and every stage of project right from the initial stage i.e. concept and planning, designing, detailing, manufacturing and execution of projects to provide customer an economical and a superfast solution for your requirement

FEATURES OF PRE-ENGINEERING BUILDING

- These buildings are easy to install.

- Dimensions of the buildings are decided as per the availability of location space.

- Optimum strength, light in weight and minimum utilization of space.

- Building materials are used strictly according to clients’ needs and demands.

ADVANTAGES OF PEB:

There are many advantages of Pre-Engineered Buildings, which are as follows,

- Quality control is the main advantage as all the structural member are engineered beforehand, standards of different codes also taken into consideration & these components are made in factory under the supervision of Quality Control Engineer.

- Lower cost due to the saving in design, manufacturing and on-site erection cost.

- Minimizing time of construction due to the use of software for design of the structural components.

- Low Maintenance due to use of standard quality of paints over steel members, which increases the ability to withstand & finally the maintenance cost will be low as compare to conventional steel building.

- Quick Erection, as all the members are Pre-Manufactured & skilled labor is used for connections of different components.

- Warranty on PEB, mostly warranty period of 20 years given by manufactures for PEB.

DISADVANTAGES OF PEB

Although PEB have many advantages in the field of Industrial structure but still there are some demerits of Pre-Engineered Buildings, which are as follows

- Rusting / Corrosion Sensitive, as if the quality of steel used or paint used for coating of steel members is not of good quality , than it can damage the structure and thus reduces the life of structure.

- Insulation Cost, as insulating the building to an agreeable benchmark will furthermore add to your construction costs.

- Appearance, Steel Sections can be unattractive when left exposed.

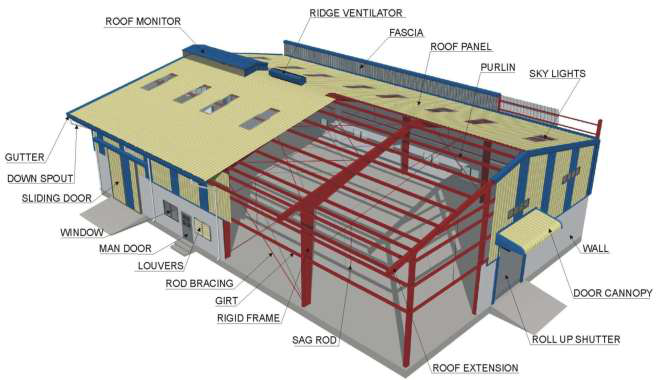

PRE-ENGINEERING BUILDING COMPONENTS

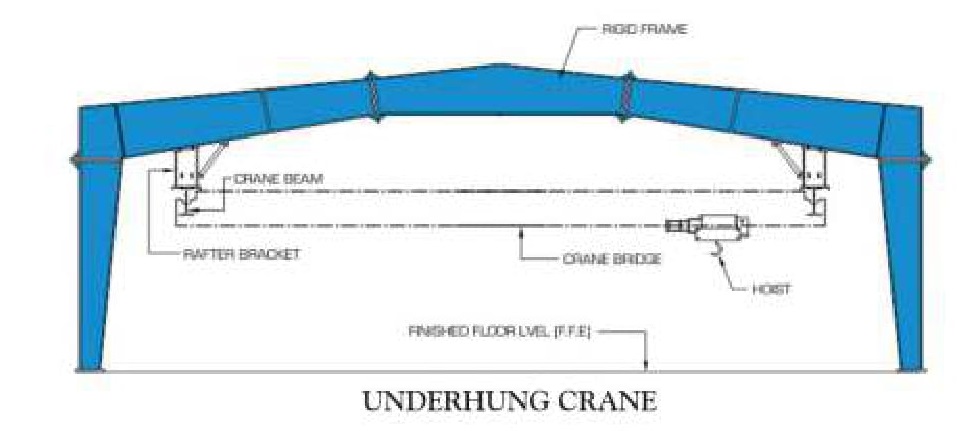

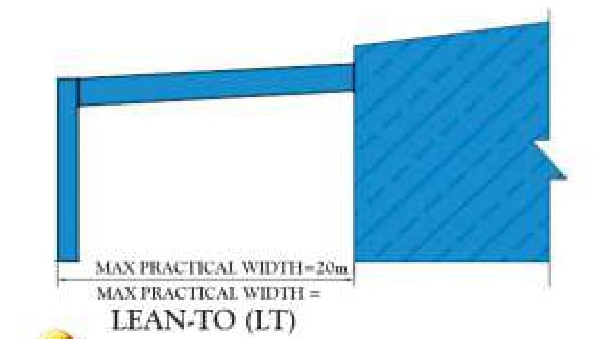

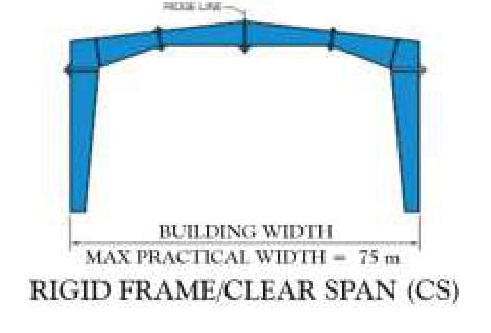

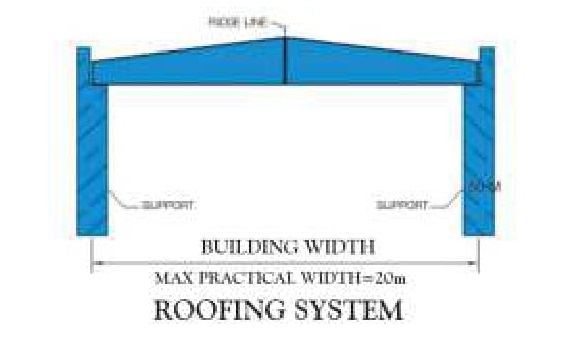

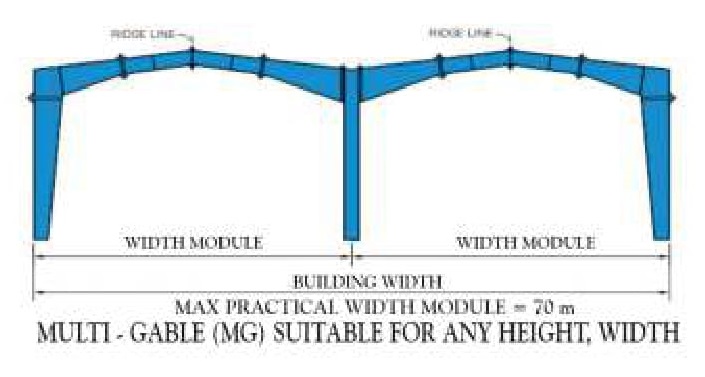

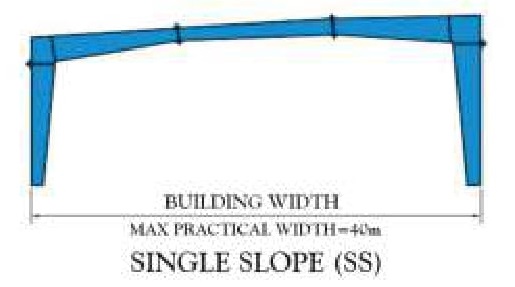

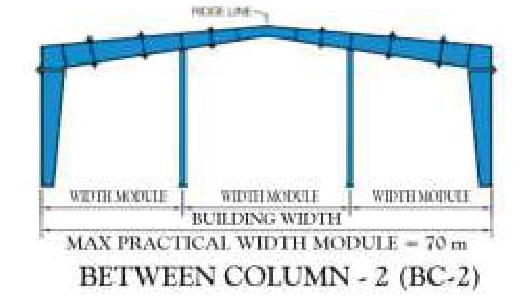

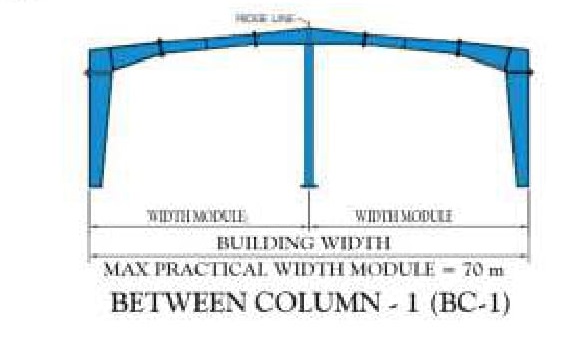

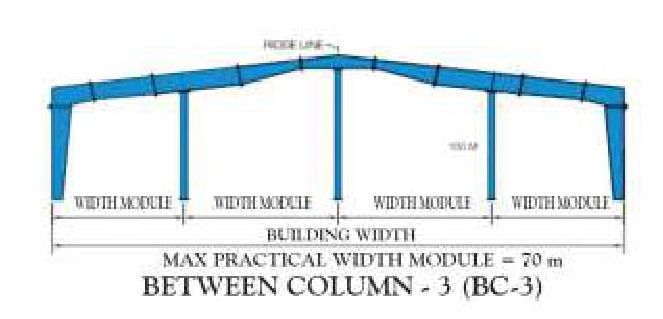

Primary Framing Systems

Comparison of Pre-engineered with Conventional Steel Buildings

| Sr.No | Property | Pre-Engineered Steel building (PEB) | Conventional Steel Buildings |

|---|---|---|---|

| 1 | Design | Design of Pre-engineered buildings is efficient due to its integral framing system. | Design of conventional buildings takes more time and it offer fewer precision design aids. |

| 2 | Codes used for Design | International design codes such as AISC, AISI, MBMA and AWS are used all over the world. | Codes are not updated and traditional codes given by IS are used. |

| 3 | Computer Software | Computer programs are available for the design of Pre-engineered buildings. Design, estimation, detailing, drawings etc. can be generated within no time using this software. | No such development is available in case of conventional buildings. |

| 4 | Structure Weight | Structural Members used are tapered built up sections and are 10 to 20% lighter than conventional buildings. | Structural Members used are Hot rolled T-sections which are of heavy weight. |

| 5 | Foundations | Since the structural weight is low, Lightweight foundation with simple design is enough. | Heavy structural weight makes it difficult to design the foundation. Foundation must be very heavy enough to bear the loads. |

| 6 | Delivery Speed | Faster delivery. It takes 6 to 8 weeks to construct 500 MT pre-engineered building after finalization of design. | Very slow delivery. It takes 20 to 26 weeks to construct 500 MT conventional building after finalization of design |

| 6 | Cost of Construction | Price per square meter is 30% less than the cost of conventional building. | Price per square meter is very much higher. |

| 7 | Seismic Resistance | These buildings offers good resistance against seismic actions since it is made of Lightweight flexible members. | These cannot withstand against seismic forces because of their rigid heavy frames. |

| 8 | Architecture | Impressive architectural options are available at low costs. | More research and time is needed. Cost also will increase. |

| 9 | Future Expansion of Building | It is easy to expand the pre-engineered building because of its simple connection design. | It requires heavy budget and also difficult to expand the building. |

| 10 | Performance | Maximum efficiency can be achieved since all the components are designed specially to act together as a system. | Components are designed individually and hence there is no guarantee about the performance of structure. |

| 11 | Responsibility | Only one supplier took the responsibility of whole project which is good for minimizing construction risks. | Multiple suppliers took the responsibilities and issues like insufficient materials, different quality components etc. may arise. |

| 12 | Clear Span | Members of pre-engineered buildings can offer large clear span up to 100 to 120 m without any intermediate supports. | Maximum clear span offered by the conventional building members is 40 m only. |

| 13 | Erection Simplicity | Erection of PEB members is so simple and faster. Light equipment is enough. | Erection in this case is slower and demands more labor. Heavy equipment is necessary. |

| 14 | Building accessories | All components of pre-engineered buildings are interchangeable at reasonable cost. | Use of specially designed accessories makes it difficult to find its replacements and increases the cost complexity of project. |