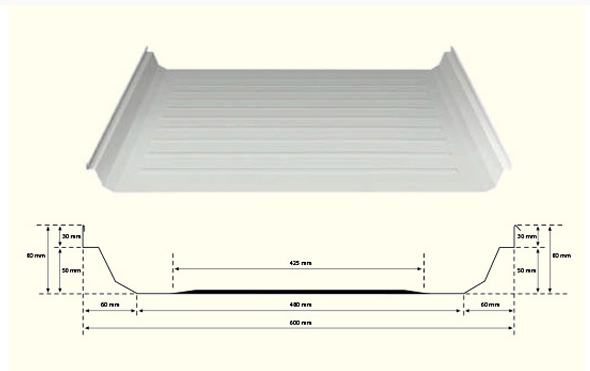

SHUBAN ZIP SEAM ROOFING

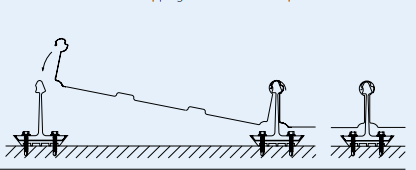

The Shuban Zip is a zip-up seam roofing system that is manufactured using state-of-the-art roll forming technology. The system can be produced either at our plant or on-site, and roll forming can also be done at eaves height. Shuban Zip Systems are available in a thickness range of 0.50 mm to 0.70 mm in bare galvalume and color-coated galvalume/galvanized steel, and in thicknesses of 0.90 mm/1.20 mm in aluminum. In addition to supplying plain mill finish, color-coated finishes are also available, which add to the overall aesthetic appeal of the roof. For information on applications and the lifespan of the sheets, please contact our technical team for further details.

BENEFITS OF ZIP SEAM ROOFING

The Shuban ZIP System has been designed for use over a wide range of construction types, providing a cost-effective solution for a variety of requirements. Our technical team assesses diverse requirements to ensure optimal performance.

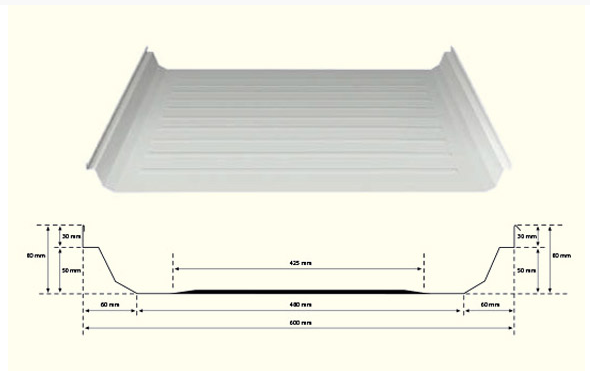

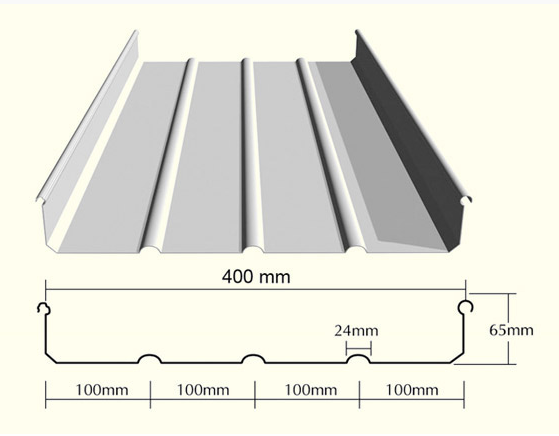

The Shuban Zip 400 and 430 systems are the most popular and cost-effective due to their wide applicability. Full support is required by incorporating a more dense type of mineral wool insulation to prevent bowing of this span.

SUBSTRATE

The substrate used for Bare Galvalume and Color Coated Galvalume is steel with an Al-Zn coating of 150 GSM minimum and yield strength of 345 MPa as per AS-1397.

We also manufacture sheets from Aluminum Alloy of the 3000 series, containing magnesium and manganese for increased strength and durability. The sheets are available in natural mill finish and color-coated finishes.

| Density | Modulus of | Thermal | Thermal Expansion | Melting Point | |

|---|---|---|---|---|---|

| Material | Kg/m3 | Elasticity Kn/cm2 | Conductivity W/m d C | In mm per d C | d C |

| Aluminum | 2705 | 6900 | 214 | 24 x 10 | 650 |

| Steel | 7850 | 21000 | 55 | 12 x 10 | 1900 |